The complete process of making Ronghua(velvet flowers)

Share

The production process of Ronghua(velvet flower) involves nine steps: silk refining(炼丝 Liansi), dyeing(染色 Ranse), sun-drying(晾晒 Liangshai), striping(勾条 Goutiao), ironing the velvet(烫绒 Tangrong), shaping(打尖 Dajian), arranging(传花 Chuanhua), adhering(粘花 Zhanhua), and packaging(包装 Baozhuang).

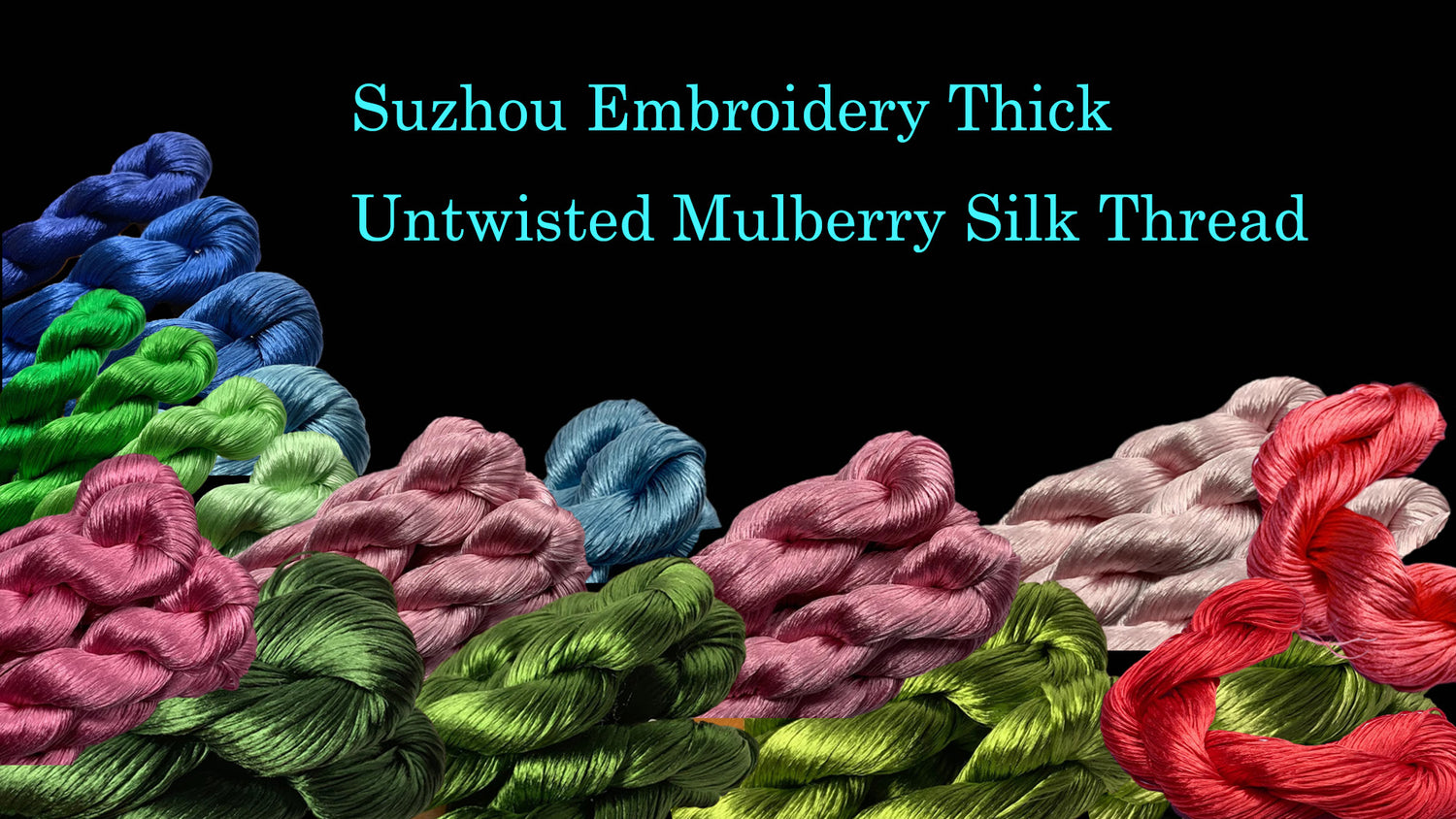

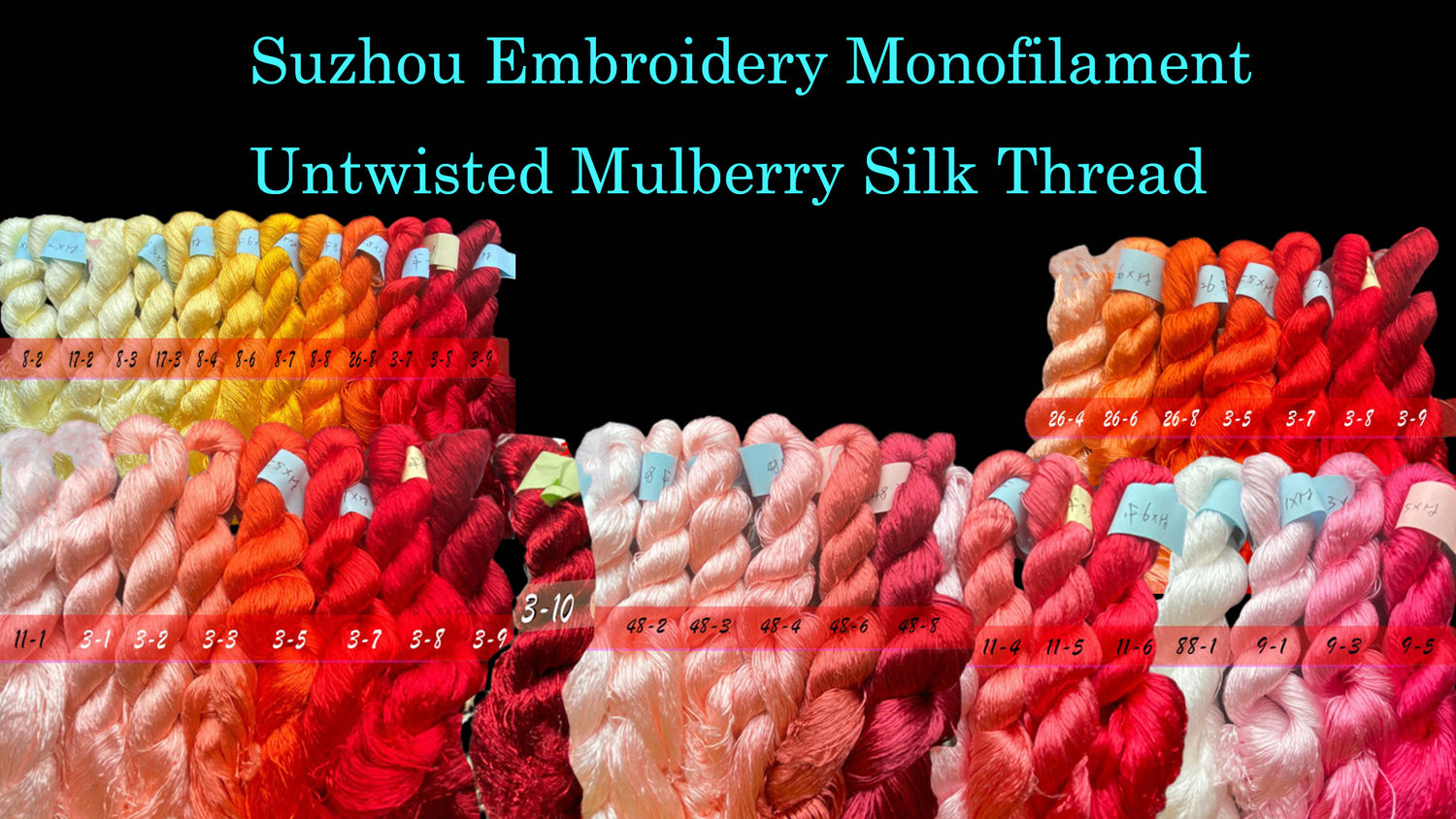

1.Silk Refining(炼丝 Liansi): The raw silk is loosened, soaked in cold water for a day, then boiled in alkali water until cooked—care is taken not to overcook it. This degummed silk thread, known as "degummed velvet"(熟绒 Shurong), possesses softness, resilience, and is resistant to shedding. Brass silk is gently heated with wood charcoal until softened.

3.Sun-Drying(晾晒 Liangshai): Dyed silk is hung on bamboo poles and left to dry in sunlight. It must be regularly turned and kept taut throughout the process.

4.Striping(勾条 Goutiao): Also known as "下料"(Xialiao),degummed velvets of various colors are cut into strips of specified lengths and widths. These strips are arranged uniformly on a specific surface. Then, using a pig bristle brush, each strip is brushed flat and even. Brass wire is folded in half, twisted slightly at one end into a fork shape, holding the arranged strips, and then twisted at the other end into a spiral shape.

The velvets are cut to the required size with scissors, twisted tightly in opposite directions, and further processed into uniform and round strips using a wooden rolling board. This process, known as "rolling velvet"(滚绒 Gunrong).Velvet Strips are crucial as the strips are the primary material and fundamental component in making Ronghua(velvet flower).

5.Ironing the Velvet(烫绒 Tangrong): Circular strips of velvet are ironed flat using a heated iron or press to create components like flower petals, bird wings, tails, feathers, etc.

6.Shaping(打尖 Dajian): Depending on the requirements of the Ronghua(velvet flower) product, circular velvet strips are cut with scissors to form blunt angles, acute angles, semicircles, spheres, ellipsoids, and other suitable shapes.

7.Arranging(传花 Chuanhua): Different colored and shaped velvet strips, processed in the shaping step, are arranged using tweezers to create three-dimensional shapes like birds, animals, insects, flowers, etc.

8.Adhering(粘花 Zhanhua): Independent velvet strips and other components such as bird beaks, crowns, eyes, tails, legs, and feet, along with auxiliary materials like lead wire, colored paper, beads, crystal beads, vegetable seeds, etc., are glued onto their respective positions using white adhesive to create the desired products.

9.Packaging(包装 Baozhuang): Depending on the creative design of the product, assembly can involve glass frames, bamboo baskets, bird nests, flower pots, and other accessories.

The above is a general process of making Ronghua(velvet flowers). Different Ronghua(velvet flowers) artists possess distinct production styles and techniques. They employ more innovative methods to bring their unique creative visions to life.You can see many videos of the process of making velvet flowers on our Instagram account: ronghuafullflowers.